District of Columbia Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma, a proven manufacturing method that has been used for decades, is now available and useful for all industries as long as practitioners know how to implement it, which has allowed the LSS industry to grow over the past ten years. It’s well-structured so organizations can see real results and improve their performance, but to reach this point, the history and details of the methodology are crucial, which means you will need to learn about them and our team at Lean Six Sigma Curriculum of District of Columbia High School Students is available to help you have a closer and clearer look to how this has evolved.

Before you make the decision to pursue certification or training, we recommend you do your research. This will help you make informed decisions about where you want to go and prepare you for your journey.

First, LSS was created to help companies prioritize customers, increase efficiency, and increase earnings.

The methodology can help reduce costs and eliminate waste if done properly. This method ensures that quality is maintained and performance is high in all this process.

This approach not only achieves the above-mentioned goals but also increases customer satisfaction and reduces lead times. It draws upon the knowledge and experience of all parties.

Lean Six Sigma improves quality and process; this is the most important thing you need to remember, and it uses two methods that are combined or merged:

- Lean is all about creating value and increasing flow.

- Six Sigma is committed to ensuring that processes are stable, efficient, and effective.

Since Lean and Six Sigma are separate methodologies, these two methods led to LSS during their combination and how people added more principles to the foundation both laid out.

LSS solved the problem of Japanese companies beating American companies in the 1980s because Kaizen, the Japanese method, helped the country’s industries achieve better results than what would satisfy their clients.

Six Sigma Principles & Origins: What You Should Know

It is essential to know the principles and logic behind Sigma and Six Sigma before you can implement Lean Six Sigma.

Six Sigma and Lean are well-known for their long existence. The first, Lean, is traced back to how Toyota invented Lean manufacturing in the late 1940s to reduce non-value-adding activity.

Lean believes employees should be actively involved in organizational change to foster excellence and that continuous learning and improvement are the two most important pillars for ensuring happiness and great results.

Toyota Production Systems (TPS) was founded by Japanese Taiichi Ohno, and the whole concept of Lean lies in those systems. The same methodology was used in Henry Ford’s Innovations and Business Process Redesign.

These are the fundamental principles that guide how it works:

- Lean starts with determining the customer’s added value.

- It is important to understand both the value stream as well as how the processes work.

- This data will enable you to identify waste and increase it, and it can then be gathered to share and reveal waste. This is the first step toward improving the process.

- Next, Lean refers to the process of setting up the system so that customers can request it, and it delivers it when they’re ready.

- Employees will be able to identify areas they need to improve and then work together to fix them. This allows for process-wide thinking and ensures everyone is focused on the customer’s needs efficiently and effectively.

Six Sigma, which uses data to identify problems and find solutions, is more focused on controlling processes so that the same problems do not happen again.

Motorola invented the method, and General Electric used it successfully. Six Sigma, a process improvement technique, dates back to 1980.

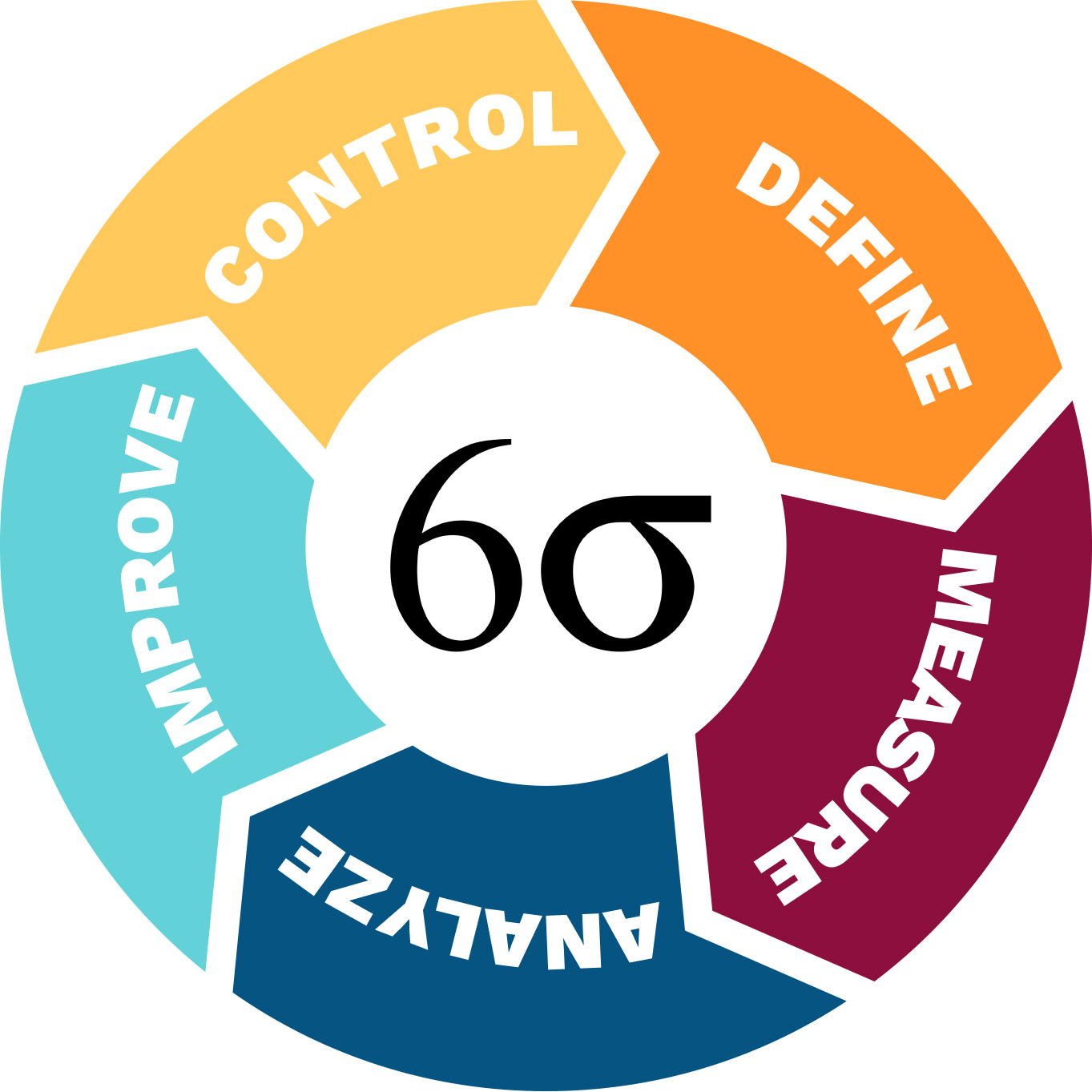

Six Sigma’s structure revolves around the DMAIC option: Define, Measure, Analyze, Improve, Control. This is useful for manufacturing but also in other industries to automate processes.

How It All Began in the USA

This was created to enable American companies to compete against Japanese manufacturers, and it is a mixture of both the existing methods mentioned earlier. However, it adds more value by setting up new standards and principles that cover the gaps between the two.

This added insight and efficiency were invaluable for the industry. This allowed for growth without sacrificing customer service.

Lean Six Sigma does not have to be restricted to manufacturing. It can also be used to improve education and healthcare, among other areas.

Participating in Lean Six Sigma can bring you many benefits, both professionally and personally. If you are interested in learning more about it or becoming certified, contact Lean Six Sigma Curriculum Pros of the District of Columbia.